-

Gat No 611 , Mouje-Kuruli, MIDC Chakan, Tal-khed Pune - 410501

Email Id - uday@excelplants.com

CallUs - +91-9225776611

OUR PRODUCTS - Auxillary Equipments Required For The Drying Plants

There are wide ranges of auxiliary equipments are used in the drying plants which are as per followings:

⇓ Industrial Blowers

Forced draft & induced draft blowers are used in the drying application. These blowers play a major role for

the process air & exhaust air handling throughout the drying application.

Forced draft & induced draft blowers are used in the drying application. These blowers play a major role for

the process air & exhaust air handling throughout the drying application.

The material of construction should

be SS316, SS304, and Carbon steel anticorrosive painted.

Features:

• Low vibration & noise levels.

• High performance & high efficiency.

• Low power consumption.

• Less maintenance.

⇓ Hot Air Generators :

The direct & indirect fired hot air generators are used depending upon the fuel to be used and product characteristics. The various fuels used for getting hot air are

• Furnace oil (FO)

• Light Diesel Oil (LDO)

• Compressed Natural Gas (CNG) or Liquefied Natural Gas (LPG)

• High Spirit Diesel (HSD)

• Saturated or supersaturated Steam

• Hot Thermic Fluid

Features :

Features :

• Low fuel consumption.

• High durability.

• Less maintenance & High efficiency.

⇓ Cyclone Seperators :

Cyclone separators are used for the separation of powder and exhaust air. Depending the capacity the cyclones are classified as mono, twin or quadruple cyclone separators.

Features :

• High efficiency rate of solids & air separation.

• Simple in construction, less maintenance.

⇓ Rotary Disc Atomizers & Pressure Nozzles :

Rotary disc atomizers & high pressure nozzles are nothing but the heart of the every spray drying process. The product characteristics are depending on the same.

Features :

• Very very good performance.

• Less maintenance.

• Gives good product quality.

• Less energy consumption.

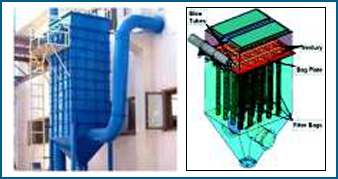

⇓ Reverse Pulse Jet Bag Filters :

Reverse pulse jet bag filters are the pollution control equipment used for the separation of fine solid particles from exhaust air. Fine particles from the exhaust air are collected from bottom discharge and clean air is then passed to the atmosphere.

Features :

• Very low emission level.

• High performance and less maintenance.

⇓ Ventury Scrubbers :

Ventury scrubber is the pollution control equipment used for the fine solid particle are dissolved in the water with water spray inside ventury and then clean air is then passed to the atmosphere.

Features :

• Low emission level.

• High performance and low maintenance.

⇓ Feed Pump ( Screw Pump, Diaphragum Pumps) :

For providing the continuous feed material to the dryer the screw pumps and diaphragm type pumps are to be used. These pump are imported from the reputed suppliers.

Features :

• Provide very high performance

• High durability and less maintenance.